In a sector where every drop counts, the ability to see, predict, and improve what’s happening underground — before problems arise — is essential. Water utilities are under pressure to manage aging infrastructure, respond to climate extremes, and serve growing populations — all while improving service and reducing costs. Digital twin technology is helping utilities meet these challenges head-on.

But what exactly is a digital twin? And what does it mean in the context of water management? Here, we break it down for you.

What is a digital twin? The digital twin definition

A digital twin is a dynamic digital representation of a physical object, system, or process. It mirrors the state, condition, and behavior of real-world assets using data from sensors, systems, and historical records. There are many applications of digital twins across sectors — from wind turbines, jet engines, aviation applications, robots in manufacturing, bridges, and even human hearts. Unlike static models, a digital twin evolves in real time, providing actionable insights for operations, maintenance, and planning.

What is a digital twin in water distribution management?

In water distribution, a digital twin links a physical water network — pipes, valves, pumps, tanks — with digital data, analytics, and models. It enables water utilities to visualize their entire water network in real or near-real time, anticipate problems before they occur, simulate different scenarios, and make better decisions faster. From minimizing non-revenue water to identifying energy inefficiencies, digital twins can help utilities plan, operate, and maintain critical infrastructure.

What industries use digital twin technology?

Although digital twins are gaining momentum in water, they’ve already proven their value across several industries:

– Construction: Digital twins in construction can track building performance and lifecycle — from design through operation — improving efficiency, cost, and sustainability.

– Manufacturing: Factories use digital twins for smart manufacturing to monitor machinery, reduce downtime, and improve productivity through predictive maintenance.

– Energy: From wind farms to power grids, digital twins help optimize generation, distribution, and equipment performance.

– Automotive: Digital twins in the automotive industry can be used to simulate vehicle performance and enhance development cycles using digital replicas of engines, parts, and systems.

– Healthcare: Digital twins are emerging in healthcare for personalized medicine, modeling human organs or patient conditions to test treatments virtually.

– Water: Utilities use digital twins to optimize water network performance, forecast demand, reduce water loss, and extend asset life — all while enhancing service delivery.

What are the benefits of digital twins across industries?

Across sectors, digital twins offer a clear advantage:

– Real-time monitoring of assets and operations.

– Predictive maintenance to prevent failures.

– Scenario modeling to test plans before implementing them.

– Cost savings from optimized performance.

– Sustainability by reducing waste and energy use.

– Data-driven decision-making at every level.

What are the benefits of digital twins in water management?

In water management, digital twins can help water utilities:

– Detect and respond to leaks: Detect leaks early through real-time monitoring and network warnings.

– Simulate operational changes: Simulate watermain shutdowns, flushing sequences, pump schedules, increased demand, and pressure zones without risk.

– Improve asset planning: Prioritize replacements using data-driven asset health indicators and performance insights.

– Reduce Non-Revenue Water (NRW): Minimize NRW through smarter network visibility.

– Respond to emergencies faster: Be prepared for weather emergencies with accurate, up-to-date system understanding. Simulate outage scenarios and recovery strategies before they happen.

– Enhance customer service: Optimizing water supply and ensure the right pressure and water quality.

– Proactive maintenance: Prevent disruptions, reduce downtime, and make proactive asset decisions by predicting failures, like risky pipes, before they happen.

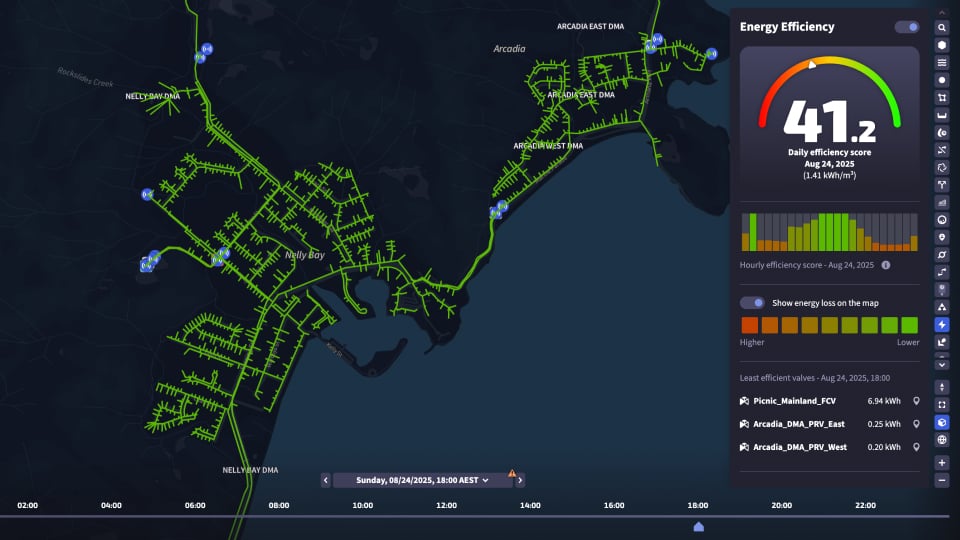

– Optimize energy use: Gain insights and understand energy dissipation in your water network by identifying inefficient network assets and understanding how much energy is being lost.

With these benefits in mind, it’s important to understand that not all digital twins are the same. Depending on their scope and purpose, digital twins can take on different forms that provide varying levels of insight and control.

Are there different types of digital twins?

Yes. Across industries, digital twins can vary by scale and function:

– Component twins: Component twins are digital replicas of individual parts, like a valve in a pipe system or a joint in a robotic arm.

– Asset twins: Asset twins are digital replicas of larger standalone units, such as pumps, tanks, wind turbines, or MRI machines.

– System twins: System twins represent entire systems, like a pump station, reservoir network, factory production line, or a city’s traffic light network, and how components in the system interact.

– Process twins: Process twins model workflows or processes over time, such as daily water distribution cycle, maintenance programs, an automotive assembly sequence, or a hospital patient intake process.

Each type offers different layers of insight that can build toward a fully integrated, comprehensive digital twin.

How do digital twins work in water management?

In water management, digital twins rely on continual data exchange between the physical system and its digital counterpart.

Here’s how a digital twin can look in water management:

– Sensors collect real-time data on flow rate, pressure, water levels, velocity, water quality, asset status, consumption, and more.

– Data integration combines sensor inputs with GIS, SCADA, hydraulic models, and historical records.

– Analytics and AI interpret patterns, forecast outcomes, and flag anomalies.

– Visualizations present this information in dashboards, maps, and simulations — turning raw data into operational intelligence.

Understanding how digital twins function sets the stage for another key distinction: how they compare to traditional hydraulic models. While the two share similarities, a digital twin goes beyond what a hydraulic model can deliver.

What’s the difference between a digital twin and a hydraulic model?

A digital twin and a hydraulic model are intertwined — there isn’t a sharp cutoff, but rather a spectrum of maturity. A digital twin goes further than a hydraulic model. A digital twin can incorporate a hydraulic model, but it also uses hydraulic behavior with real-time telemetry, asset data, historical data, operational logic, and AI. You might say that a hydraulic model becomes a digital twin when it goes beyond being a static engineering tool and is continuously synchronized with your real water system.

Here’s an example of how the process from hydraulic model to digital twin may look for a water utility:

1. Hydraulic model (baseline)

Built from design drawings, GIS, and system data.

Used for planning, “what-if” scenarios, simulations, and design.

Updated only when engineers make changes.

2. Calibrated hydraulic model

Adjusted so that simulated results match observed field data (flows, pressures, tank levels).

Trusted for operational decision-making — but still mostly offline and manually updated.

3. Dynamic hydraulic model

Connected periodically to operational data (SCADA, meters).

Updates more frequently, but often still used in snapshots rather than continuously.

4. Digital twin

Fully integrated with real-time or near real-time data streams.

System state (demands, pump operations, tank levels) is constantly refreshed.

Can run simulations automatically (predictive/optimization scenarios).

Provides operators with decision support, forecasting, and alerts.

The eventual goal of a digital twin is that it’s always up to date and it continuously pulls in live data, learns over time, and reflects the current state of the physical system. You might think of it as the difference between a photograph and a live video feed. While a photo shows you a moment, the goal of a digital twin is to give you insight into a real time dynamic, living system.

Where is your water utility on its digital twin journey?

At Qatium, we envision the digital twin journey in four stages — from a digital replica to a full-blown water intelligence platform.

1. Digital replica — the foundation

The first stage in the digital twin journey is where you create a “digital replica.” A digital replica is a static digital model of your network. Your digital replica is your foundation, and it should be fairly quick and easy to create if you’re using the right platform.

Qatium’s water management platform helps you create a digital replica in minutes using an easy model builder. You can import your old models if you have them or create a model with GIS data alone — no hydraulic modeling skills required. Simply drag and drop your network files into Qatium, and you’ll see results in a few minutes. Q is Qatium’s digital water assistant, and they’ll guide you through the process and fill in any data gaps you might have as well.

2. Digital shadow — a real-time view

The second stage of the digital twin journey is to build a “digital shadow.” Your digital shadow is a critical step in the digital twin journey because it’s where you begin to create a real-time view of your water network by integrating live data streams from meters, sensors, or IoT devices. Qatium’s live data connection seamlessly integrates your SCADA, AMI, and IoT data and allows you to automatically adjust your model to reflect real-world conditions more accurately.

3. Digital twin — operational control

The third stage is when your digital twin starts to come to life. At this stage, your digital twin becomes an integral part of your control room and operational decision-making. This means that not only do you have real-time visibility into your water network, you also have workflows, procedures, and possibly digital connections that ensure the insights your digital twin gives you are translated into real-life action in your water network.

For example, your digital twin detects a sudden drop in pressure in one part of the network, you quickly test different scenarios to identify the cause and most optimal solution, then dispatch precise orders to field crews.

At the digital twin stage, decisions in the control room are based on your digital twin intelligence, and that intelligence is translated into coordinated action on your water network in the field.

4. Water intelligence platform — all intelligence connected and amplified by AI

The most advanced stage on your digital twin journey is when all your utility intelligence — human intelligence, system intelligence, and artificial intelligence (AI) — is integrated and driving proactive performance across your water network and your organization. At this stage, interoperability is critical. For your water intelligence platform to be fully realized, the software you use must be able to talk to other systems running in your utility. An open water platform gives you the flexibility to adapt your digital twin to your utility’s needs and requirements.

For example, maybe you connect your digital twin to your work order application so when you run an operational scenario, you can automatically send the tested operational procedure to your field team to execute. Or perhaps your CRM system is integrated with your digital twin, and customer complaints or feedback are automatically triangulated with network intelligence.

At the water intelligence platform stage, there’s an additional layer of AI on top of your digital twin that understands what it’s seeing, can answer questions in plain language, and make suggestions. The AI may have some kind of control in your digital twin or across systems, autonomously analyzing cross-system intelligence, testing scenarios, and recommending action.

What are the first steps toward a digital twin for your water utility?

A successful digital twin journey starts with a clear objective — whether it’s reducing leaks, improving energy efficiency, or preparing for growth. Start by:

1. Assessing existing data and systems

2. Identifying high-value use cases

3. Choosing a scalable, utility-focused platform

4. Engaging your operations and IT teams early

5. Building a roadmap for phased implementation

Every water utility can create a digital twin, regardless of size and resources

If a fully realized digital twin seems out of reach — don’t get discouraged. Keep these three things in mind:

It’s a journey: Building a digital twin for your water distribution management system is an ongoing process, developing over time and never fully “done.”

Every digital twin composition is different: Every water utility’s digital twin maturity will be different depending on their systems, data, needs, and goals.

You have support: The right partner will give you the support you need to develop a digital twin for your unique water management system and utility — you don’t have to figure it all out from scratch.

Qatium is a water management software that helps water utilities like yours develop your digital twin at a pace and scale that works for you. Our technology and dedicated customer support team make each stage adaptable and approachable for every water utility regardless of your network or organization’s size.